The TQ-60-X is a high-performance ultrasonic flaw detector designed for simultaneous operation with two 64-channel phased array probes and a variety of scanners, including roller scanners and combined PA+TOFD scanners. With an S-scan refresh rate of 100 Hz, it enables high-speed weld inspection from both sides at up to 6–9 meters per minute.

The device also supports up to two TOFD channels, meeting global inspection standards. A classic flaw detection mode is included. An advanced software package provides automated data collection, image processing, and 3D visualization for detailed evaluation.

Application

- Weld inspection using phased array and TOFD techniques

- Automated scanning with 2D scanners

- Defect detection in metal structures

- High-speed, high-resolution inspection of complex geometries

- Post-scan 3D analysis and reporting

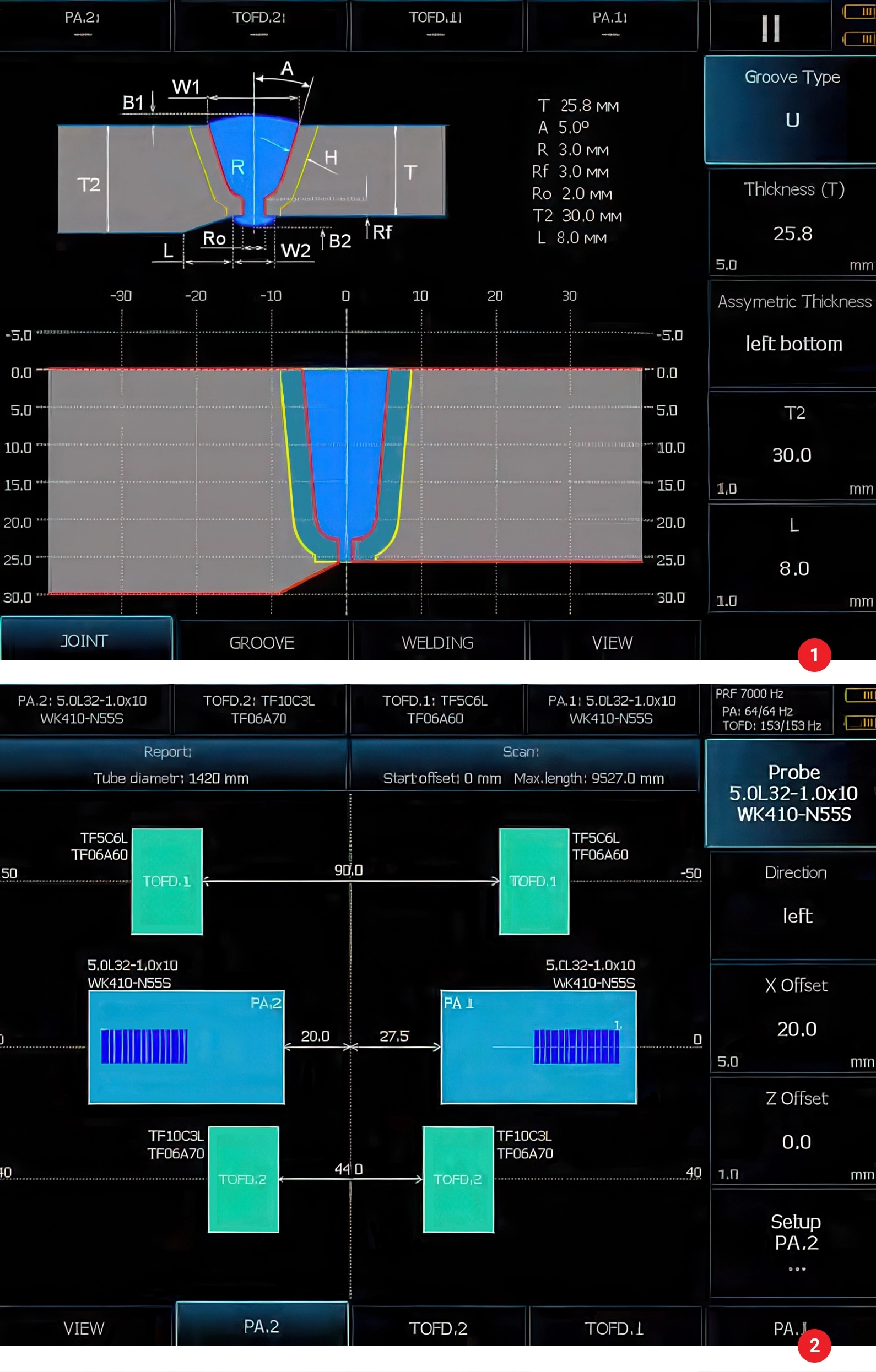

- Supports full weld geometry definition, including wall thickness differences, cap bead dimensions, and heat-affected zone width (image 1)

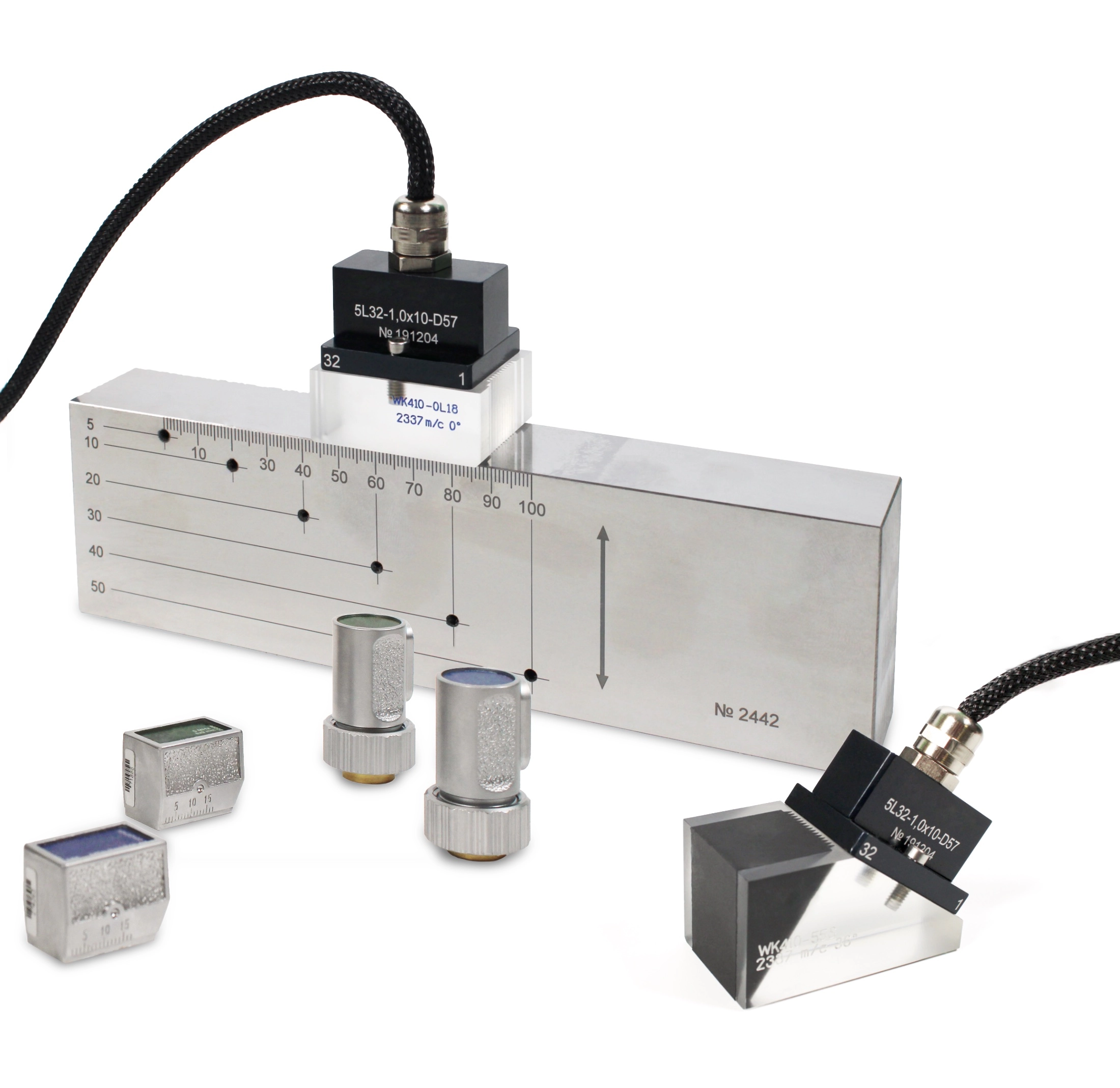

- Universal, clearly structured probe positioning on the scanner ensures precise data alignment into a unified scan (image 2)

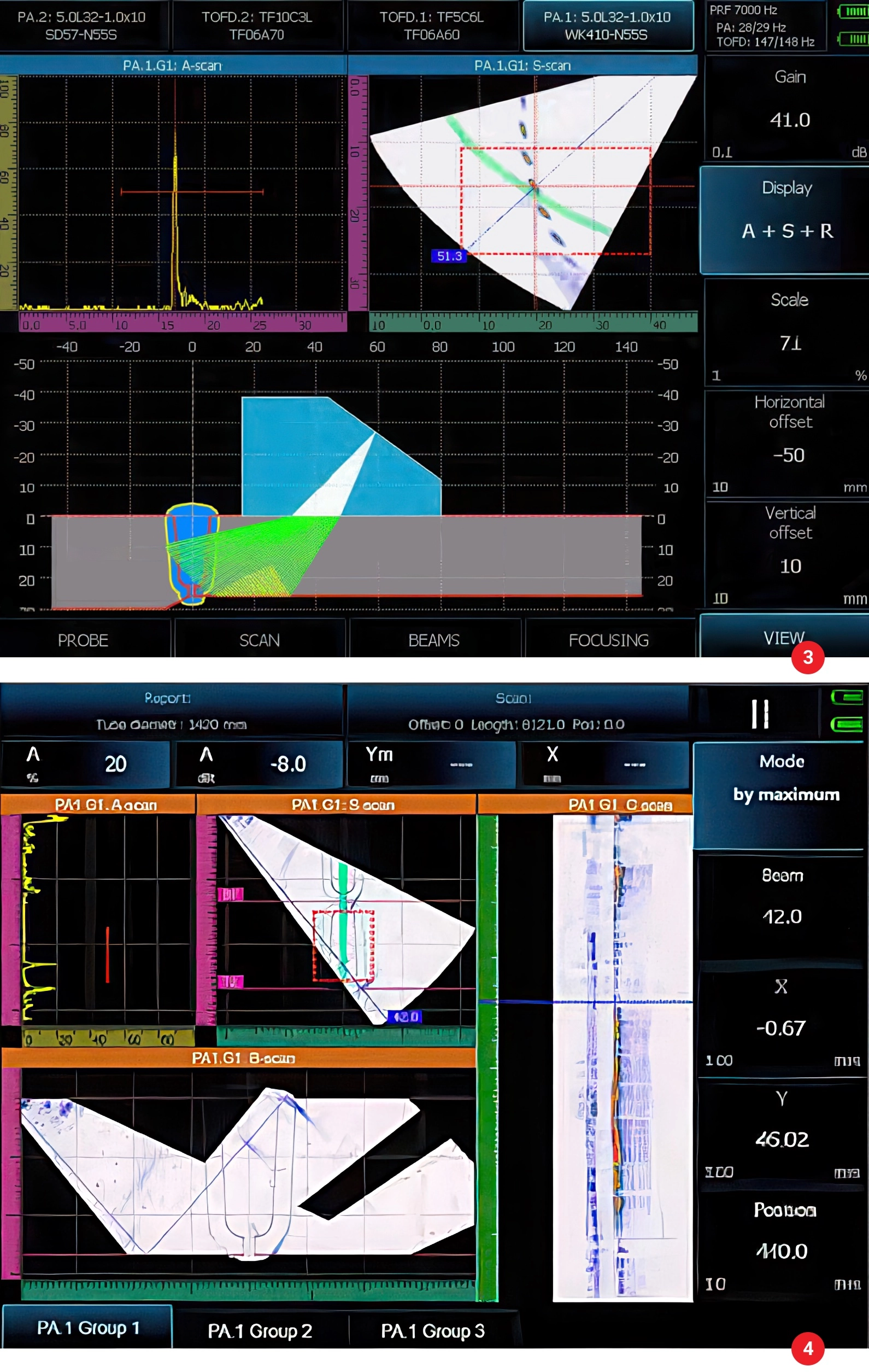

- Up to 4 inspection groups can be configured for each phased array probe

- High-resolution imaging with multiple scanning types:

– Classic S-scan

– Fixed-angle L-scan

– Combined LS-scan (compound S-scan with beam swing and aperture movement

Phased array (PA) channels:

- Generator configuration: 16:128 (optional 32:128)

- Excitation voltage: ±75 V

- Pulse type: Radio pulse

- Synchronization: by position encoder or by time

- Gain: 0–80 dB (0.5 dB step)

- Operating frequency range: 500 kHz – 20 MHz

- Sampling rate: 100 MHz

- ADC resolution: 10 bits

- Data resolution: 16-bit

- Signal recording: Digital recording of each waveform

- Maximum A-scan length: up to 10,000 points

- Pulse repetition frequency: Up to 20 kHz

- Number of focal laws: up to 1024

- Sensitivity leveling: 2D by angle and depth (TCG range 60 dB, 32 points with slope up to 50 dB/μs)

- Focus types: depth, path, distance, auto

- Decimation: 1:1 / 1:128

Single-element (conventional UT) channels:

- Number of channels: 2 independent

- Excitation voltage: ±200 V

- Operating frequency range: 500 kHz – 20 MHz

- Sampling rate: 100 MHz

- Gain: 0–110 dB (steps: 0.1 / 0.5 / 1 / 2 / 6 dB)

- Processing modes modes: A-scan, B-scan, TOFD

- Connectors: 4 x Lemo 000

Storage: USB flash or Ethernet (10/100 Mbps)

USB ports: 2 onboard + hub for 5 additional

Data file size: up to 300 MB

Standard scanning speed: 6–9 m/min

Scan length: 5000 measurements

Display: 8.5" TFT, 800x600, contrast mode for sunlight

Power: 2 swappable batteries, up to 12h operation

External power: 220 V AC

Operating temperature range: from -35 °C to +50 °C

Dimensions: 280 × 245 × 100 mm

Weight: 2.5 kg (with battery)