Probe K (HV5) is specifically designed with reduced dimensions to facilitate hardness control in confined spaces such as inside pipes, tanks, and other hard-to-reach places. Its compact size allows for efficient testing in areas where standard probes may not fit.

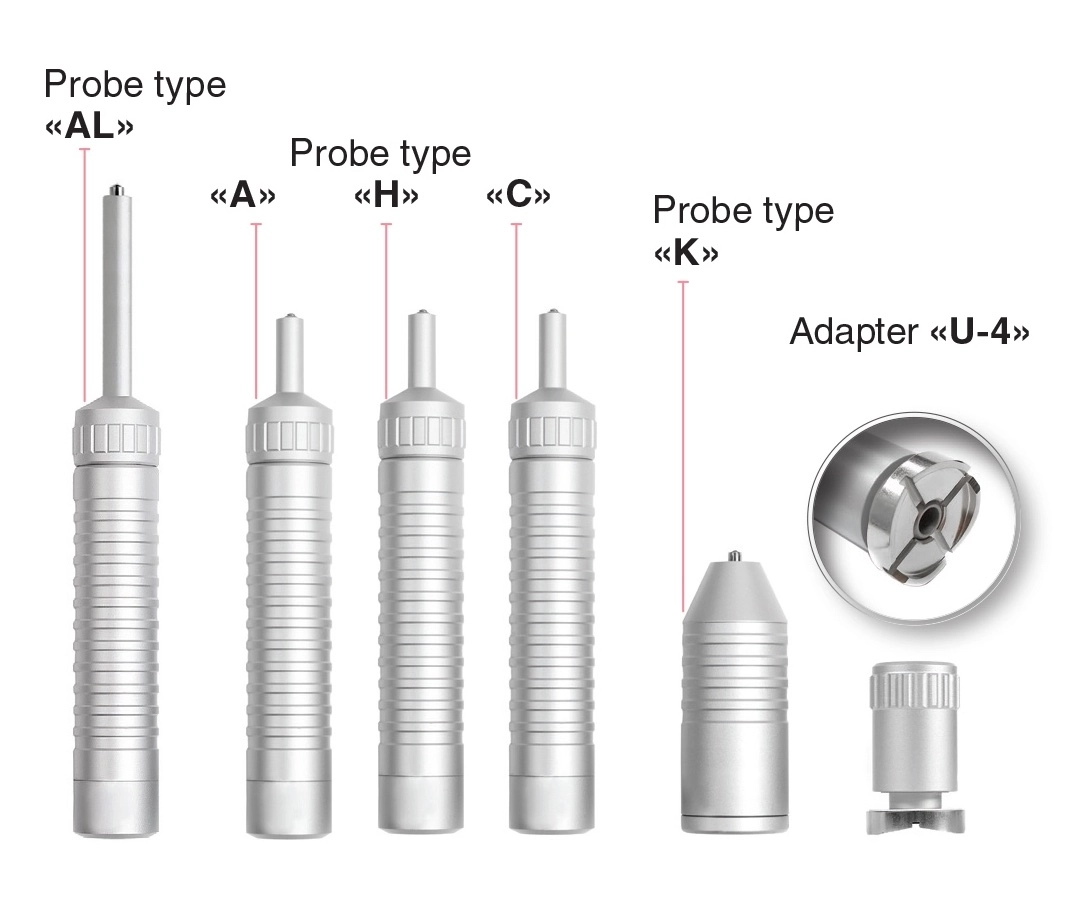

The design of hardness testers TQ-4C provides full interchangeability of probes.

Application

- Carbonaceous and structural steels.

- Items with surface-hardened layers such as cementation, nitride hardening, and high-frequency current hardening.

- Heat-proof, corrosion-proof, and non-corrosive steels.

- Plated coatings (chrome) and overlaying.

- Items of complicated configurations.

- Stable readings independent of force and time of pressing.

- The spatial position of the sensor does not affect the measurement result.

- Easy measurement in hard-to-reach areas.

- Ultra-small control area (from 1 mm).

- Invisible print on mirror surfaces.

- Low sensitivity to the curvature of surfaces, thickness, and weight of the product.

Probe K (HV5) is specifically designed for measuring hardness inside pipes, tanks, and other confined spaces, making it ideal for applications where standard probes cannot reach.

Requirements

- Items heavier than 1 kg and thicker than 3 mm require no additional preparation.

- Items lighter than 1 kg should be fixed in a vice clamp or on a support plate using fixing paste.

- Items with a thickness of less than 3 mm should also be fixed using fixing paste.

- The roughness of the controlled surface providing the best measurement accuracy is 1.6 RA.

Attention

A built-in Lemo plug-in is integrated into the probe. The connection cable is sold separately.

-2.webp)