The Leeb rebound hardness test method was developed in 1975 is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces, mainly above 1 kg. It is well-suited for testing ferrous and non-ferrous materials and can be converted to various hardness scales like Vickers, Brinell, Rockwell C & B, and Shore.

Principles of Leeb hardness testing method

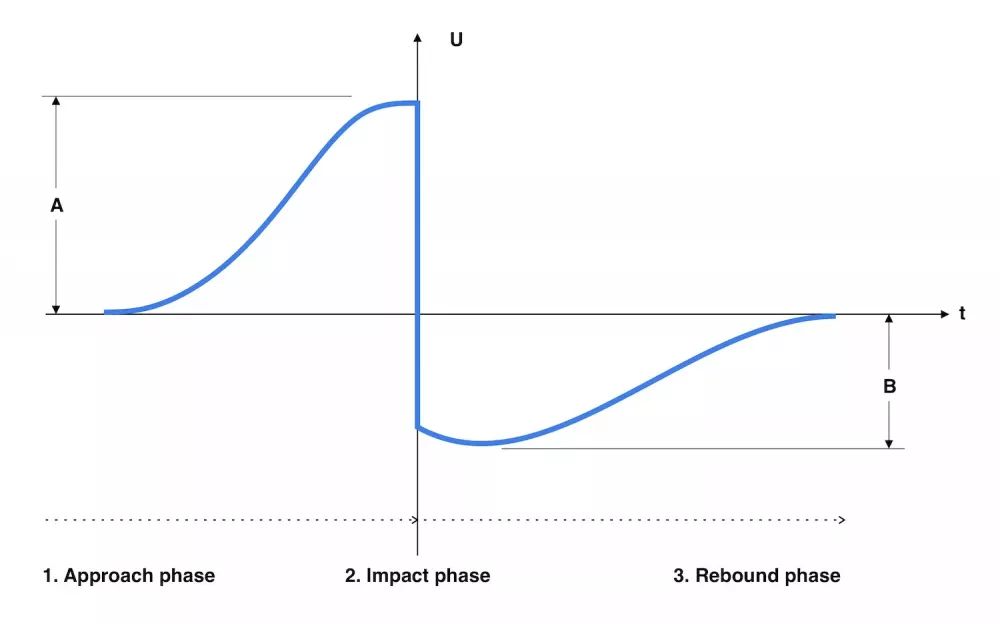

The Leeb method employs a dynamic technique where the hardness of a material is determined by the ratio of the rebound velocity to the impact velocity of a moving impact body. This method is particularly suitable for solid parts like castings and forgings.

The test involves the impact of a specimen body on the surface being tested, followed by the measurement of the rebound velocity in comparison to the incident velocity. The results obtained are directly related to the hardness of the material being tested, with higher hardness leading to increased hardness values and rebound speeds.

A – Peak value of the approach phase. B – Peak value of rebound phase. t – Time. U – Voltage

Advantages of using portable equipment for Leeb hardness testing method

-

Portability and accessibility: Portable hardness testing equipment offers the advantage of being easily transportable and accessible for on-site testing without the need to move large or heavy components to a laboratory. These portable devices allow measurements to be taken directly on the spot, eliminating the need to cut samples or transport them to a testing facility, enhancing convenience and efficiency.

-

Versatility and application range:Portable hardness testers provide versatility in testing various materials, including steel, cast iron, stainless steel, bronze, aluminium alloys, brass, and copper, making them suitable for a wide range of applications. The ability to measure hardness in different positions and directions, along with the capability to test a variety of materials, enhances the versatility and applicability of portable hardness testing equipment.

-

Cost-effectiveness and efficiency:Portable hardness testers offer a cost-effective solution for hardness testing, especially for large components that are challenging to test using conventional benchtop methods. These devices provide a quick, economic, and non-destructive testing solution, allowing for efficient hardness measurements in a matter of seconds, saving time and resources.

-

Ease of use and technology: Portable hardness testing equipment is designed to be user-friendly, with features like high contrast LCD screens, automatic angle adjustment systems, internal data storage, USB connectivity for data transfer, enhancing ease of use and data management.

Leeb hardness testing using TEQTO’s TQ-3C series

Application of the Leeb method

The application of portable Leeb hardness testers is diverse and includes various industries and scenarios. Here are the key applications based on the provided sources:

- Failure analysis: In failure analysis of pressure vessels, steam turbine generator sets, and other equipment, portable Leeb hardness testers play a crucial role in assessing the hardness of components to identify potential weaknesses or defects. By conducting hardness tests on critical parts, these devices help in diagnosing failures, determining material properties, and ensuring the integrity and safety of equipment in various industrial settings.

- On-site testing: Portable Leeb hardness testers are designed for on-site testing of heavy, large, or installed parts, making them ideal for applications where moving the test samples to a laboratory is impractical or impossible. These devices allow for quick and convenient hardness testing directly at the location of the component, eliminating the need for sample transportation and reducing testing time and costs.

- Mechanical assembly parts: Portable Leeb hardness testers are widely used in installed mechanical assembly parts for hardness testing. They provide a practical solution for assessing the hardness of various components in mechanical assemblies, ensuring quality and reliability. The ability to measure hardness directly on assembled parts without disassembly makes portable Leeb hardness testers valuable tools for quality control and maintenance in mechanical applications.

- Material sorting: Portable Leeb hardness testers are used for material sorting in metal material warehouses, where quick and accurate hardness measurements are essential for categorising materials based on their hardness properties. These devices enable efficient sorting of metal materials based on their hardness levels, ensuring proper material selection for specific applications and enhancing material management processes in warehouses.

- Heavy workpieces and limited spaces: Portable Leeb hardness testers are suitable for testing heavy workpieces with very limited space, where traditional benchtop testers may not be practical or feasible. The compact size and portability of these devices allow for hardness testing in confined spaces or on large workpieces where access is restricted, providing flexibility in testing various components.

Types of materials

The Leeb hardness testing method is versatile and applicable to a wide range of materials. Here are the key types of materials suitable for Leeb hardness testing:

- Metals: Leeb hardness testing is commonly used for testing various metal materials, including alloy steel, stainless steel, grey cast iron, ductile iron, steel, iron, aluminium, and copper. This method is particularly effective for measuring the hardness of steel products, cast steel, and cast iron, making it a valuable tool for assessing the hardness of metallic components in different industries.

- Alloys: The Leeb hardness tester is suitable for testing alloys, which are combinations of metals or a metal with other elements. Alloys like alloy tool steel, copper, bronze, and other metal alloys can be effectively tested using the Leeb hardness testing method. The ability to measure the hardness of alloys accurately is essential for quality control and material characterization in industries where alloy components are prevalent.

- Ceramics: While not explicitly mentioned in the provided sources, the Leeb hardness testing method can also be applied to ceramics. Ceramics are materials that can undergo hardness testing to evaluate their resistance to deformation and scratching, making them suitable candidates for Leeb hardness testing. The hardness of ceramics is crucial in applications where surface integrity and resistance to scratching are essential factors for performance and longevity, highlighting the importance of hardness testing in this material category.

- Other materials: The Leeb hardness testing method can also be used for testing materials beyond metals and alloys. The versatility of the Leeb hardness tester allows for testing a wide range of materials, including elastomers, polymers, plastics, films, rocks, and minerals, depending on the specific application requirements and material characteristics.

Industries

Here are the industries that commonly use the Leeb hardness testing method:

- Manufacturing industry: The manufacturing industry extensively uses the Leeb hardness testing method to measure the hardness of materials like steel, iron, aluminium, and copper. This industry relies on hardness testing for quality control and ensuring that components meet specified hardness requirements. Hardness testing is fundamental in manufacturing processes to assess the durability, strength, and quality of materials used in producing a wide range of products across different sectors within the manufacturing industry.

- Mechanical engineering: In mechanical engineering, Leeb hardness testers are employed for testing installed mechanical assembly parts, bearings, screws, bolts, and other mechanical components. This application ensures that mechanical parts meet hardness standards for performance and reliability. The ability to measure hardness in various mechanical components is crucial for maintaining quality standards and ensuring the integrity of mechanical systems in industries such as automotive, aerospace, and machinery manufacturing.

- Construction industry: The construction industry utilises Leeb hardness testing for inspecting stationary structures like bridge halls and pipes used for oil and gas transport. Hardness testing in this industry helps ensure the structural integrity and safety of construction materials and components. By assessing the hardness of construction materials, the construction industry can verify material quality, durability, and suitability for specific applications in building infrastructure projects.

- Heavy machinery and equipment: Industries dealing with heavy machinery and equipment benefit from Leeb hardness testing for analysing failure in pressure vessels, steam turbine generator sets, and other equipment. This application helps diagnose failures and determine material properties critical for equipment safety. The ability to conduct hardness tests on heavy workpieces with limited space is particularly valuable in industries where large machinery components need to be tested for hardness properties.

- Metal material warehouses: Metal material warehouses use Leeb hardness testers for material sorting based on hardness levels. This application ensures proper categorization of metal materials according to their hardness properties, facilitating efficient material management processes within warehouses. By employing Leeb hardness testing for material sorting, metal material warehouses can streamline inventory management and ensure that materials are used appropriately based on their hardness characteristics.

Limitations

The Leeb hardness testing method, while widely used for assessing material hardness, has certain limitations that users should be aware of.

- Sample weight and rigidity: One of the key limitations of the Leeb hardness testing method is related to the weight and rigidity of the sample being tested. If the sample lacks sufficient weight and rigidity, it can absorb much of the impact, leading to inaccurate results. The ideal sample weight for accurate testing is ≥5kg (10lbs), and samples below this weight may require additional support or coupling with a heavier material.

- Sample preparation: The preparation of the sample surface is crucial for accurate hardness testing. Samples should have a flat, clean, and metallic shine surface without oxide layers, rust, or other contaminants. Any alterations to the sample through cold processing or thermal processing can affect the accuracy of the hardness test results.

- Surface roughness and curvature: The surface roughness of the sample at testing points must meet specific requirements (Ra ≤ 1.6), and the curvature radius of the testing and nearby surface should be larger than 30mm. If the sample surface is not flat, appropriate supporting rings should be used, and the tester probe must be as close to perpendicular to the test surface as possible throughout the test.

- Sample Thickness and Absorption Layer: Samples must be thick enough and have a sufficient surface absorption layer for accurate hardness measurement. The thickness of the sample and the surface absorption layer requirements vary based on the type of impact device used. Samples that do not meet these thickness requirements may lead to inaccurate hardness measurements.

- Magnetization and temperature: Samples should not be magnetised, as the magnetic field can interfere with the impact device signal, leading to inaccurate results. Additionally, the surface temperature of the sample should be less than 250°F (120°C) to ensure accurate hardness testing

- Test location and edge distance: The test location should be a minimum distance from the edge of the part to avoid edge effects. It is recommended to test a minimum of 5mm (0.2 inches) from the edge, with 10mm (0.5 inches) or greater distance being preferable for accurate hardness measurements.

In conclusion, the Leeb hardness testing method offers a portable, efficient, and versatile solution for assessing the hardness of a wide range of materials across various industries. While the method provides numerous advantages such as portability, cost-effectiveness, and ease of use, it also comes with certain limitations that users should consider for accurate and reliable hardness measurements.

Understanding the principles of the Leeb hardness testing method, its application range, and the types of materials suitable for testing is essential for utilising this technique effectively. Industries such as manufacturing, mechanical engineering, construction, heavy machinery, and metal material warehouses benefit from the practicality and convenience of Leeb hardness testing in ensuring material quality, structural integrity, and equipment safety.

By acknowledging the limitations related to sample weight, rigidity, surface preparation, roughness, curvature, thickness, magnetization, temperature, test location proximity to edges, users can optimise their hardness testing processes and enhance the accuracy of their results. Proper sample handling and adherence to testing guidelines are crucial for mitigating these limitations and obtaining precise hardness measurements.

Overall, the Leeb hardness testing method remains a valuable tool for quality control, material characterization, failure analysis, and material sorting in diverse industrial settings. By balancing its advantages with an awareness of its limitations and best practices, users can leverage the benefits of Leeb hardness testing to ensure the reliability and performance of materials and components in their respective applications.

TEQTO’s answer to portable Leeb hardness testing: TQ-3C series

The TQ-3C is another high-precision handheld instrument engineered for demanding production and field conditions. Operating on the Leeb method, this tester provides robust control over the hardness of various materials, including structural, tool, corrosion-proof, heat-proof, and non-corrosive steels and alloys, as well as alloys of nonferrous metals, cast iron, aluminium, bronze, and brass. It is suitable for measuring the hardness of components with surface hardening and high-frequency current hardening, as well as complex-shaped items.

-hardness-tester-tq-3c-special-2.webp)