- Description

- Exploitation

- Technical specifications

- Delivery set

- Additional equipment

COMBI hardness tester TQ-4Combi – portable precision device with brand-new soſt ware.

Device is intended for non-destructive testing of production quality in metallurgy, mechanical engineering, aircraft, shipbuilding, atomic industry, oil and gas industry.

Applying TKM-459CE combi you receive all advantages of UCI and Leeb methods of metals and alloys hardness control.

TQ-4Combi controls hardness of following:

- Carbon and structural steels as well as other fine-grained materials

- Hard-surfaced items (cementation, nitride hardening, high frequency current hardening)

- Heat-resistant, corrosion-resistant, stainless steels

- Non-ferrous metals and alloys (cast iron, aluminium, bronze, brass)

- Electroplated coating (chrome, copper, nickel, zinc, tin), overlaying

- Items of complex configuration (gear teeth, shafts, pipes of any diameter, grooves, blind holes)

- Thin-walled and small-sized items

- Large items and heavy-duty equipment (gas pipelines, rails, construction elements)

Exploitation advantages

Features of TQ-4Combi

- Impact-, dust- and water-proof housing.

- Bright color display allows to make measurements at below zero temperature.

- Signalization about exceeding of prescribed measurement threshold.

- Unique statistical data processing system.

- Fast calibration of device scales with one or two standard test blocks.

- Flexible device memory for readings recording and analysis.

- Programming of additional calibrations for scales of hardness tester with one or two standard test blocks.

- Fast programming of additional scales with two to ten standard test blocks.

Probes characteristics

Requirements for the objects of control

| Preparation | UCI method | Leeb method |

| Need no additional preparation |

Weight 1 kg or more

Thickness 2 mm or more

|

Weight 5 kg or more

Thickness 6 mm or more

|

| Need to be fixed on the base plate |

Weight less than 1 kg

Thickness less than 2 mm

|

Weight less than 5 kg

Thickness less than 6 mm

|

| Roughness requirements | 0.8 – 3.2 Ra (depending on probe) | 3.2 – 7.2 Ra (depending on probe) |

Hardness testers modes

| Measurement mode | Readings | Using |

| By basic scales | Basic hardness units (HRC, HB, HV) | Hardness testing of the bulk of products |

| By additional calibrations to basic scales | By HRA, HRB, HSD scales and ultimate tensile strength | Hardness testing of high-alloy steels, special cast iron and nonferrous metals |

| By additional scales | Scales are programmed by the user | Special problems solving |

The parameters of the statistical processing of measurements

- Maximum, minimum, mean value, standard deviation from the mean.

- The average deviation from the values set by a user, results are more/less the values, the maximum deviation in the large/smaller side of the value.

- Number of results outside the upper/lower limit of range (user specified), maximum deviation from the upper/lower border.

- Automatic garbage results, incorrect measurement.

- Comparison of results of measurements in the series (the comparison charts on the display of the hardness tester).

| Characteristic | Values |

| Relative average error at regular calibration | 3-5 % |

| Hardness testing ranges: | |

| Rockwell C | 20-70 HRC |

| Brinell | 90-450 HB |

| Vickers | 240-940 HV |

| Spot diameter on the item surface for probe positioning | From 1 mm on flat surface From 5 mm in a slot |

| Quantity of possible additional scales calibrations | 5 for each scale |

| Quantity of additional scales | 3 |

| Duration of the measurement | 2 seconds |

| Quantity of measurements for average reading calculation | 1-99 |

| Memory capacity | 12 400 readings |

| Maximum quantity of named blocks of readings generated in memory | 100 |

| PC connection | USB |

| Power supply | Li-ion accumulation battery |

| Dimensions of hardness tester electronic unit | 121x69x41 mm |

| Weight of electronic unit | 0.3 kg |

| Weight of A-probe | 0.3 kg |

| Weight of D-probe | 0.15 kg |

| Operating temperature range | -15…+35 °C |

| Warranty | 1 year |

| Elements | Hardness tester TQ-4Combi |

Hardness tester TQ-4Combi+ |

| Electronic unit with accumulation battery | + | + |

| A-type probe | + | + |

| D-type probe | + | + |

| Connecting cable for A-type probe | 1 pcs | 2 pcs |

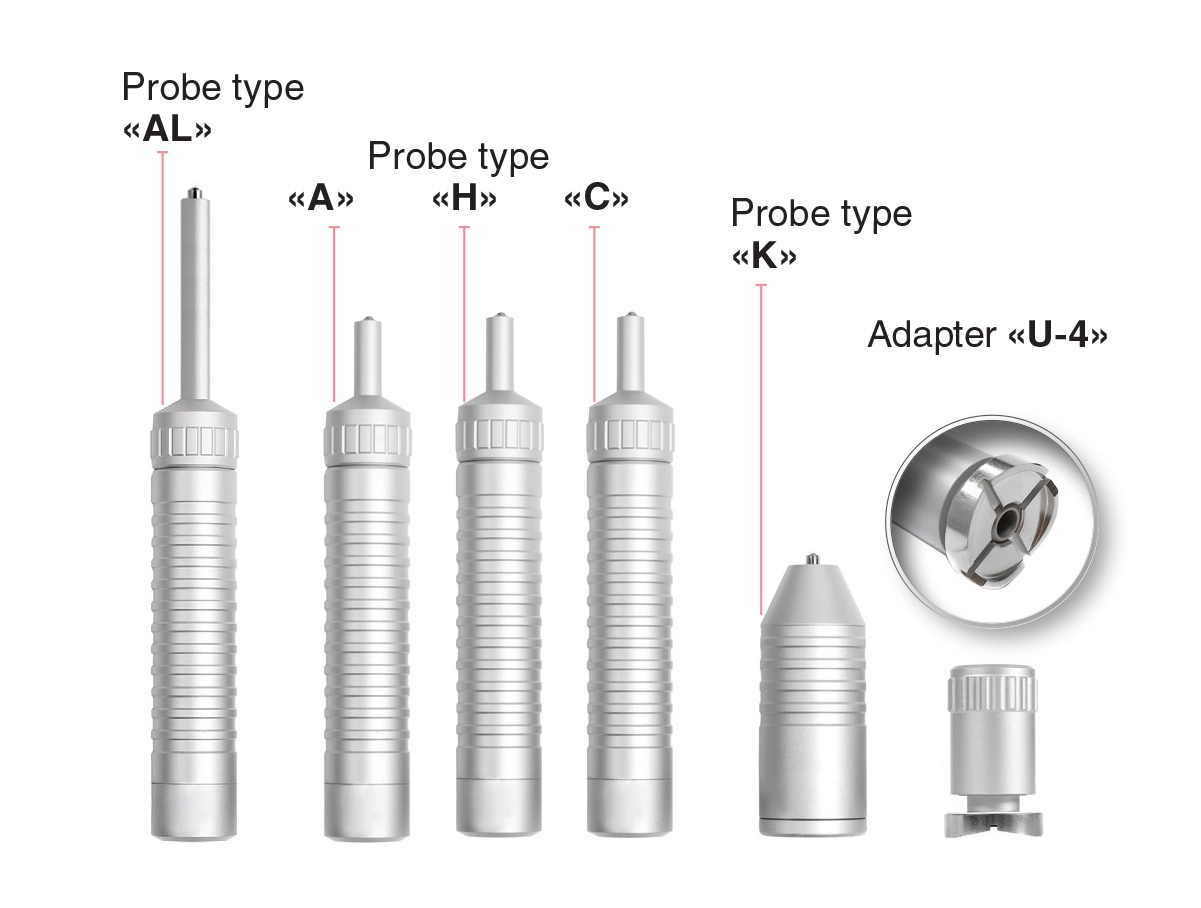

Adapter “U4” |

+ | |

Adapter “Z3” |

+ | |

| Standard test block HRC | + | |

| Standard test block HB | + | |

| Standard test block HV | + | |

| Charger | + | + |

| Operating manual | + | + |

| PC cable | + | + |

| Soft case | + | + |

| Cuff to fix device on arm | + | + |

| Bag for carrying and storing | + | + |

ACCESSORIES

- Replaceable probes of different construction and load

- Special heads to facilitate positioning of the probe on complex surfaces

- Connection cables

Adapter “U4” for positioning of probe on flat, curved, cylindrical surfaces.

Minimum diameter of controlled item is 4 mm.

Adapter “U4” is purposed for following UCI probes:

- Probe A (HV5)

- Probe H (HV1)

- Probe C (HV10)

Probe AL (HV5) for hardness tester TQ-4C

– in small diameter holes up to 62 mm deep,

– between the teeth of the gears,

– in grooves, recesses, etc.

Probe AL (HV5) is purposed for hardness measurement of following:

- Carbonaceous and structural steels;

- Items with surface-hardened layers such as cementation, nitride hardening, high frequency current hardening;

- Heat-proof, corrosion-proof, non-corrosive steels;

- Plated coating (chrome), overlaying;

- Items of complicated configuration.

Advantages

- Stable readings independent from force and time of pressing.

- Easy measuring in hard-to-reach areas.

- Ultra-small control area (from 1 mm).

- Control in slots and blind holes from 5 mm (not provided by rival devices).

- Invisible print on mirror-surface.

- Low sensitivity to the curvative of surface, thickness and weight of product.

Probes characteristics

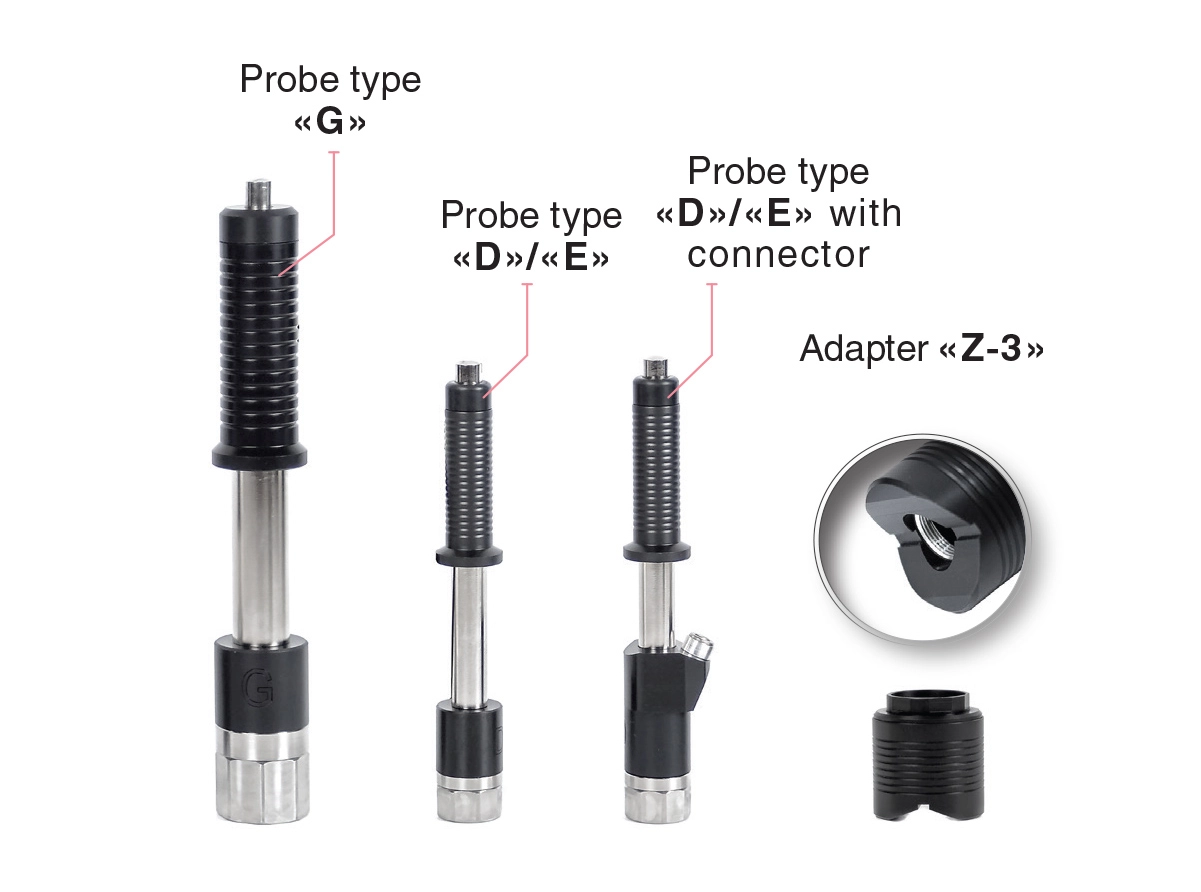

ATTENTION! There is a built-in Lemo plug-in in the probe. Connection cable is sold separately.

The design of hardness testers TQ-4C provides full interchangeability of probes!

Probe E is a replaceable probe for Leeb Hardness tester TQ-3C.

Probe with indenter made of polycrystalline of boron nitride intended for control of materials with high hardness.

The Probe E is used for hardness testing:

- All basic types of metals and alloys without additional calibrations (structural, tool, corrosion-proof, heat-proof, non-corrosive steels and alloys as well as alloys of nonferrous metals, castiron, aluminium, bronze, brass).

- Items with surface hardening and high frequency current hardening.

- Items of complicated configuration.

- Heavy and big items with rough surface.

Advantages of Leeb probe

- Hardness measurement in hard-to-reach areas.

- The spatial position of the probe does not affect the measurement result.

- The robust housing is not subject to mechanical stress.

- Long service life.

Probes characteristics

ATTENTION! If you buy only Probe E, the Hardness tester TQ-3C should be sent to the retrofit and alignment.

Probe D is included in the Basic delivery set of the Leeb Hardness tester TQ-3C.

The Probe D is used for hardness testing:

- All basic types of metals and alloys without additional calibrations (structural, tool, corrosion-proof, heat-proof, non-corrosive steels and alloys as well as alloys of nonferrous metals, castiron, aluminium, bronze, brass);

- Items with surface hardening and high frequency current hardening;

- Items of complicated configuration;

- Heavy and big items with rough surface.

Advantages of Leeb probe

- Hardness measurement in hard-to-reach areas.

- The spatial position of the probe does not affect the measurement result.

- The robust housing is not subject to mechanical stress.

- Long service life.

Probes characteristics

ATTENTION! If you buy only Probe D, the Hardness tester TQ-3C should be sent to the retrofit and alignment.