For professionals requiring precise hardness measurements on small, thin, or complex-shaped components, TEQTO’s UCI (Ultrasonic Contact Impedance) method hardness testers offer an exceptional solution. The UCI method is particularly well-suited for testing on materials that are difficult to assess with traditional methods, such as weld seams, coatings, and small parts.

TEQTO’s UCI hardness testers are designed for portability, allowing you to conduct thorough hardness inspections directly on-site, even in hard-to-reach areas. These devices are ideal for industries such as aerospace, automotive, power generation, oil and gas, where precision and non-destructive testing are critical.

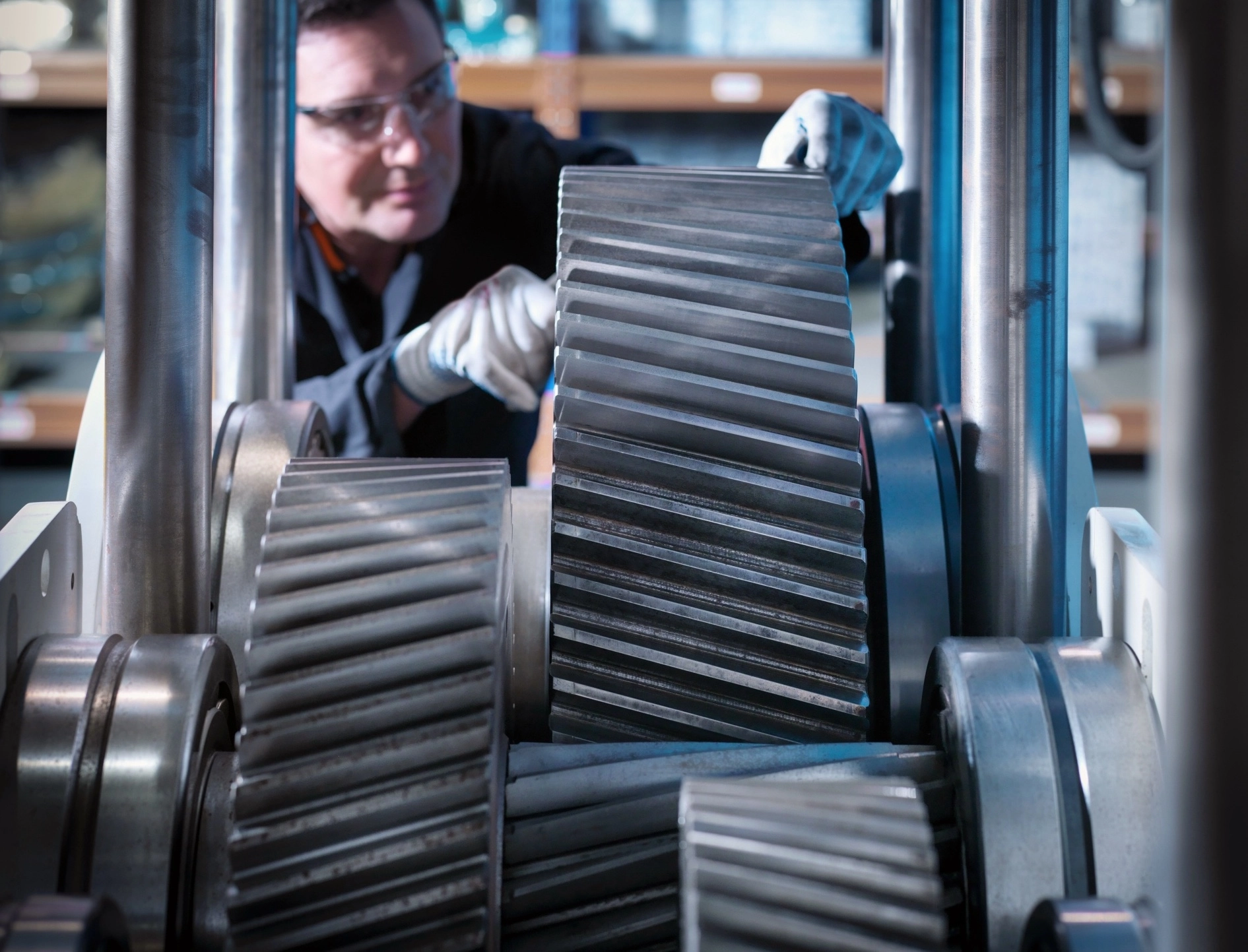

Our comprehensive range of accessories enhances the performance and versatility of our testing equipment. With specialized probes, adapters, and cables, these tools are engineered for high-quality standards, ensuring precise and reliable results across various applications. They extend your equipment's capabilities and support accurate measurements.

Crafted for durability and ease of use, our accessories are designed to meet diverse testing needs. They deliver consistent results across different materials and conditions, optimizing your testing processes and maintaining the integrity of your equipment.